Ditch Assist DIG™ | Ditch the Laser. Dig Up to 75% Faster.

Real-time RTK depth & grade guidance—simple, wireless, and laser-free. One operator, no stopping, no extra systems required.

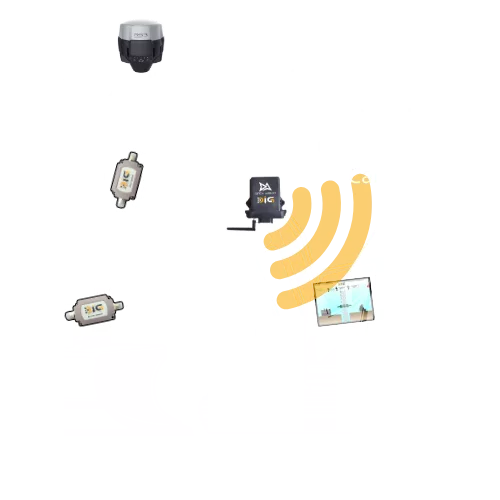

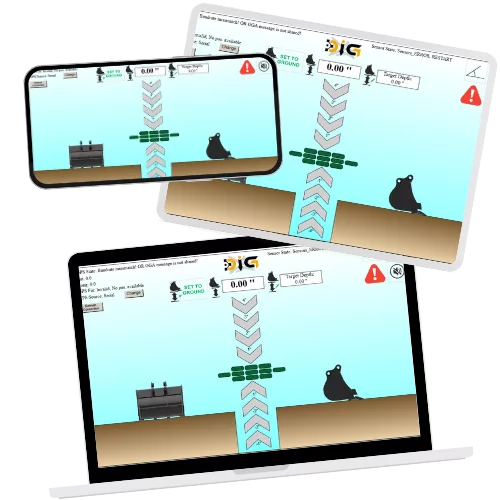

See Your Grade in Real Time as You Dig

Live on-screen guidance that moves with your bucket—no laser, no stopping, no guesswork.

Ditch Assist DIG™ brings accurate, real-time grade guidance to any excavator or backhoe. Using RTK GPS and smart sensors, DIG™ displays precise cut/fill guidance that responds instantly to bucket movement, ensuring every pass stays on grade.

The web-based interface is intuitive, fast to set up, and works on any tablet or laptop—no proprietary displays or complex systems to learn. Ideal for contractors, municipalities, and operators who need reliable grade accuracy without the cost and overhead of full machine control.

From straight-line drainage runs to multi-pass grading, DIG™ keeps results consistent, repeatable, and professional.

Not a 3D System — And That’s the Point.

Most operators don’t need full 3D machine control just to dig to grade. DIG gives you the accuracy you need without the complexity, training, or $80k–$120k price tag of 3D systems. If you outgrow DIG, great — but most users find DIG does everything they actually need, faster and simpler.

Think You Need a Full 3D System? Maybe Not. If you don’t already run 3D, chances are you don’t need it to dig accurate grade.

It’s easy to assume you need a full 3D machine control system with mapping and import capabilities to get “professional” results. The truth? Most operators never use 80% of what those systems can do — and many who buy them end up frustrated, under-trained, or avoid using them altogether. We know because we've replaced dozens with our simpler systems!

Ditch Assist DIG™ focuses on what most real-world jobs actually require:

✅ Accurate grade and slope in real time

✅ Simple setup and fast learning curve

✅ Works on any jobsite, with one operator

❌ No CAD uploads, no file prep, no complexity

If you truly need 3D automation with full CAD support, we won’t pretend to replace it — those systems have their place and a pricepoint that is fair given their complexity.

If your job needs stakes and common sense, not an engineering department — DIG is the right tool. Importing CAD, aligning coordinate systems, and preparing machine files sounds impressive… but most operators tell us it slows them down more than it helps. DIG gets you working in minutes, not hours.

Key Features of Ditch Assist DIG

✅ The fastest, simplest way to add RTK grade guidance to any excavator

Ditch Assist DIG™ is a purpose-built, standalone guidance system that gives excavator and backhoe operators real-time RTK depth and slope feedback—without needing the full Ditch Assist platform. A compact DIG controller, rugged inclination sensors, and wireless connectivity deliver precise bucket guidance at any boom, stick, or bucket position.

Set up in minutes, connect with any web-enabled device, and start digging with confidence. DIG is designed for simplicity, accuracy, and everyday usability—no complex learning curve, no wires through the cab, and no extra hardware required.

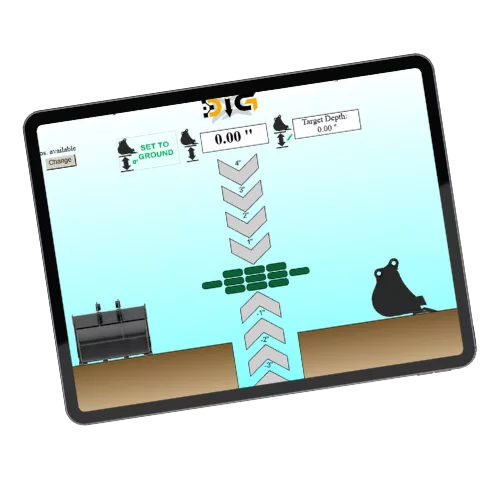

✅ Bring Your Own Screen

No special display needed. DIG™ runs from a web browser, so you can use the tablet or laptop you already own. Connect to the DIG Wi-Fi, open the link, and you’re working. The interface is clean and easy to follow, so operators of any experience level can stay on grade with zero fuss. Need a ready-to-go device? We can provide a configured tablet.

✅ Wireless Connectivity — No Cables, No Hassle

✅ Accurate Real-Time Bucket Guidance on Any Machine

✅ Ultra-Rugged, High-Accuracy Inclination Sensors

✅ Universal GPS Compatibility

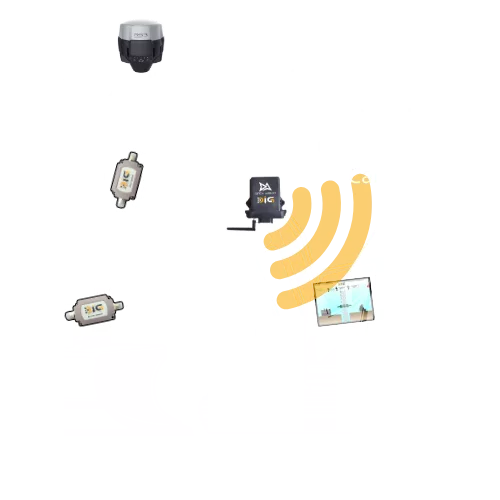

Ditch Assist DIG™ comes with everything you need for standalone excavator grade guidance—and we can supply the rest if you want a complete, ready-to-run kit. The core DIG kit includes the DIG controller, wiring, dual rugged inclination sensors, and our GPS pendulum mount for accurate bucket elevation tracking.

You have flexibility in how you complete your setup:

• Display: Use any tablet, iPad, or laptop with a web browser—no proprietary screen required.

• RTK GPS: Bring your own receiver, or we can provide a simple, reliable turnkey RTK package if you're new to GPS.

Whether you already have RTK and a device in the cab—or want a fully preconfigured system delivered to your door—DIG™ adapts to your needs. We’ll guide you through the best setup for your machine, your budget, and your comfort level with technology, ensuring a smooth and stress-free path to precise, real-time grade guidance.

Ditch Assist DIG Components

Have Questions about Ditch Assist DIG?

We'd love to chat! Talk to one of our product specialists today

Typical Ditch Assist DIG Setup

GPS Pendulum Mount

The mount mast is typically permanently installed (welded) on the machine, positioned at the top of the stick so that the pendulum pivot point is above the boom-stick pivot.

Control Module

The Ditch Assist DIG™ Control Module can be conveniently mounted outside near the cab using the provided magnet mounts. A single power cable connects to the machine's battery, one cable interfaces with the GPS receiver, and a dedicated cable connects to the two sensors.

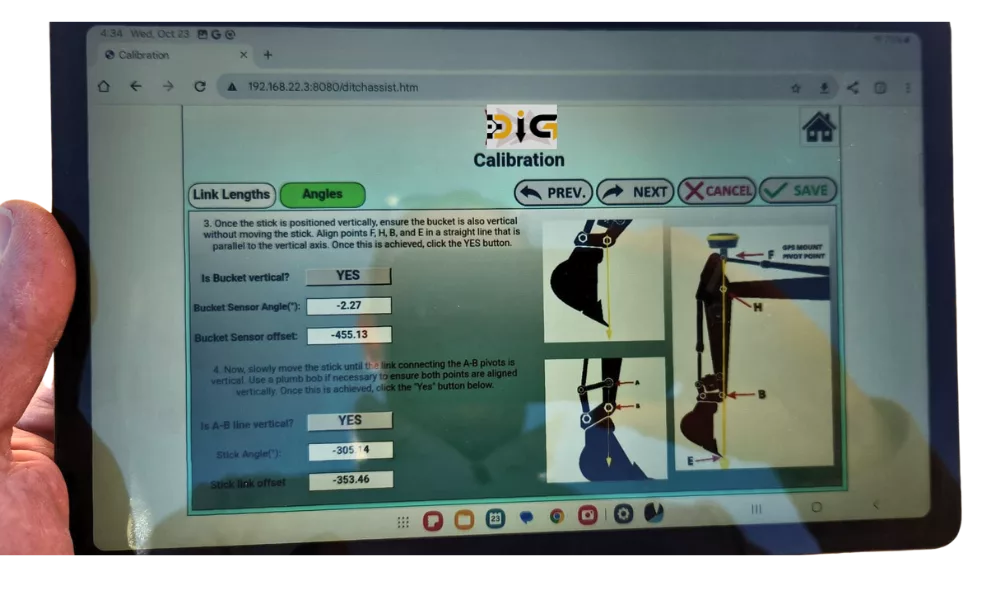

Calibration Steps

Calibrating Ditch Assist DIG™ is quick and straightforward thanks to the built-in, step-by-step guide in the DIG web interface. No apps to install and no software to download—just connect to the DIG controller’s Wi-Fi, open your browser, and follow the on-screen illustrated instructions.

The calibration walks you through a few simple machine positions and basic measurements to teach DIG the geometry of your boom, stick, and bucket (or dogbone). You’ll just need a step ladder to reach the GPS when vertical, a metric tape measure, a level, and a plumb bob.

The entire process typically takes under 20 minutes, and your calibration is saved to the DIG controller. You’ll only need to recalibrate if sensors are moved or the system is transferred to another machine. If you switch machines often, keeping your measurements handy allows for fast re-entry next time.

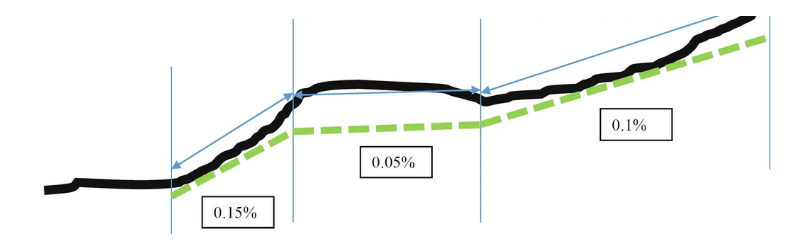

Start at the outlet, enter your first slope, dig to grade, reset at each break, and continue. Use DIG’s Point-to-Point Survey to check slopes between key points before you dig.

The graphic above shows a simple example of how to use Ditch Assist DIG™ to re-grade a ditch or trench with multiple slope changes.

The black line is the existing ground elevation. The green dashed line is your desired finished grade. You’ll typically begin at the outlet or lowest point—place the bucket on the ground, set your reference, and enter your first target slope (e.g., 0.15%). DIG provides live cut/fill guidance as you dig.

When you reach a planned grade change, stop at that point, “zero” the bucket to create a new reference, enter the next slope (e.g., 0.05%), and continue. Repeat at each break until the job is complete. This step-by-step process ensures a clean, consistent finish and proper drainage end-to-end—without lasers or rework.

Pro Tip:

Before digging, you can use DIG’s Point-to-Point Survey feature to quickly check the natural slope between two or more locations. Simply touch the bucket to the ground at Point A, then drive to Point B and do the same—DIG instantly displays the grade between them. This helps you confirm your design is achievable and decide where slope changes should occur (A-B, B-C, C-D, etc.) before you start cutting dirt.

Which Excavator Guidance System is Right for You?

We offer two excavator guidance options because operators have different needs—not because one is “better” than the other. The right choice depends on how you work.

Ditch Assist DIG™ — Fast, Simple, Standalone Grade Guidance

DIG is for operators who want the simplest, most cost-effective way to dig to grade with RTK accuracy. It’s a dedicated excavator solution—no extra hardware, no DA system required, and no design prep or mapping knowledge needed.

Best for:

✔ Digging to a set grade (municipal drainage, contractors, trenching, tile mains, water/sewer runs, culvert work, slope maintenance)

✔ Operators who value speed, simplicity, and low cost of ownership

✔ Crews that don’t need mapping, designs, or CAD-style workflows

Why choose DIG:

-

Purpose-built for excavators

-

Set grade → dig → done

-

Fastest to learn and use daily

-

No Ditch Assist system required

-

Typically 1/2 the cost of X (complete system)

DIG is the 80% solution for 80% of excavator jobs — and the one operators actually use every day.

Ditch Assist X — Advanced Surveying & Design for Power Users

Ditch Assist X is for operators who want survey, mapping, and design tools on top of grade guidance. It’s an expansion of the full Ditch Assist system, so it’s ideal for users who already own DA or who want the flexibility to use both excavators and surface equipment with one platform.

Best for:

✔ Users who want to survey, design, and plan jobs in the field

✔ Creating best-fit or multi-segment designs (e.g., curved ditches, grade optimization)

✔ Users already running Ditch Assist on scrapers, ditchers, or blades

Why choose X:

-

Survey and map your route before digging

-

Design slopes, breaks, and variable grades

-

Import simple design files with target elevations

-

Works with the full Ditch Assist app ecosystem

-

Ideal if using DA on multiple machines

If you need to design jobs before digging, X gives you those tools. If you’re mostly digging to a known grade, DIG is the smarter fit.

✅ What Both Systems Do

Both DIG and X will let you:

✔ Dig to a fixed elevation or set grade

✔ Maintain correct slope between two points

✔ Use grade breaks for multi-segment runs

✔ Install quickly, run wirelessly, and use RTK for high accuracy

Both are 2D guidance tools — focused on keeping the bottom of your trench/ditch on grade.