Wolverine Ditcher™ Grade Control with Ditch Assist

Ditch Assist™ is the simplest and most affordable RTK GPS grade control system for Wolverine ditching implements. Advanced features. No unlocks or subscriptions.

Using Ditch Assist with Wolverine Ditchers: An Overview

The Wolverine Ditcher – a heavy-duty rotary ditcher combining scraper-like cutting with wide soil spreading – can transform field drainage when paired with Ditch Assist’s automation. Ditch Assist is a next-generation grade control system that goes beyond what old laser or manual methods can achieve. It automates your Wolverine’s hydraulic lift with sub-inch accuracy across any terrain, eliminating tedious laser setups or guesswork. The plug-and-play kit works on any brand of ditcher or tractor, and you get all advanced features upfront with no subscriptions or unlock fees. In short, adding Ditch Assist lets you cut ditches faster, easier, and more precisely than ever – making traditional laser levels and expensive OEM grade-control packages a thing of the past.

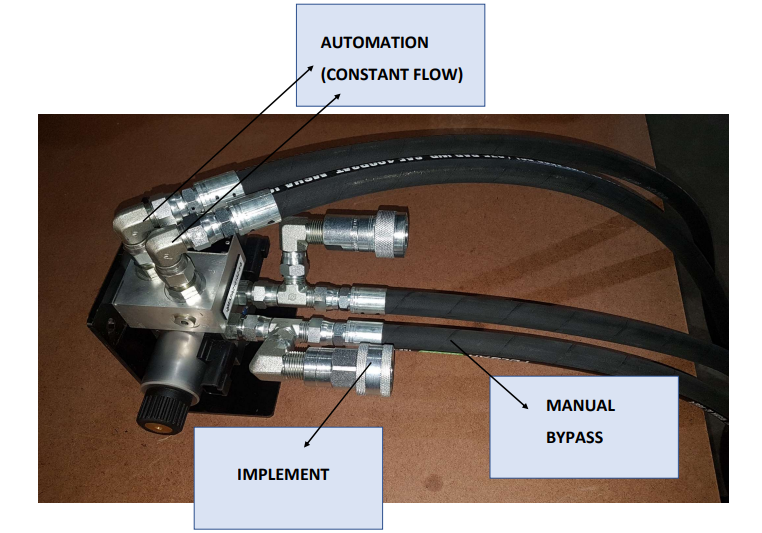

A popular setup for Wolverine Ditcher owners is the Ditch Assist Full Automation Kit, which includes everything needed to equip the implement with automatic grade control. This kit provides a rugged proportional hydraulic valve plus all necessary hoses and fittings to tie into your Wolverine’s raise/lower hydraulics. Uniquely, the kit features a hydraulic bypass circuit so you can always operate the ditcher’s hydraulics manually via your tractor controls whenever needed. In other words, Ditch Assist adds hands-free automation without taking away your ability to make manual adjustments at any time – a reassuring feature for operators who want that flexibility. The result is seamless integration: your Wolverine Ditcher’s cutting depth can be controlled automatically by Ditch Assist’s computer, but you retain full manual override instantly if desired.

👉 Interested in upgrading your Wolverine Ditcher? Get a Quote or Free Consultation and discover how easily Ditch Assist can fit your operation.

RTK GPS Compatibility: Use Existing Systems or Affordable Options

Grade control accuracy is only as good as the positioning data it receives, so Ditch Assist is built to leverage high-precision RTK GPS for true sub-inch accuracy. The system is completely GPS-brand agnostic – as long as your receiver outputs standard NMEA messages (virtually all do), you can feed its signal into Ditch Assist and get straight to work. This means you can likely use the GPS equipment you already own. For example, many users tie Ditch Assist into John Deere, Trimble, Outback, or Ag Leader receivers on their tractors, provided those receivers are unlocked for RTK or another high-accuracy signal. If your current setup isn’t RTK-ready, you have options: you could unlock or upgrade your existing receiver through your GPS dealer, or opt for a cost-effective RTK solution. One popular affordable choice is the Emlid Reach series (such as the RS3 units), which offer full RTK capability at a fraction of the cost of traditional systems. Ditch Assist interfaces seamlessly with these, giving you an economical path to high-accuracy grade control. In short, “any RTK GPS” will work – you’re free to use your existing RTK setup, upgrade a capable receiver, or purchase a low-cost unit to pair with Ditch Assist, whatever suits your operation. This freedom to mix and match means Ditch Assist fits into your precision ag toolkit without forcing you to buy proprietary GPS hardware or subscriptions. If you’re unsure about compatibility or need guidance on GPS options, our team is ready to help. The bottom line: Ditch Assist works with virtually any RTK GPS source, so you won’t be locked into a single brand ecosystem or left needing expensive brand-specific hardware to get started.

Simple Setup and Compatibility with Your Tractor

Even if you’re not particularly tech-savvy, setting up Ditch Assist on a Wolverine Ditcher is straightforward. The system was designed with simplicity in mind. The included quick-start guide walks you through mounting the GPS antenna (typically on the ditcher frame for best accuracy), installing the valve (with simple quick-connect hoses to your tractor’s remotes and to the ditcher’s lift cylinder), and plugging in the power. Since the interface runs on a standard Android tablet, there’s no complex hardware to wire into your cab – just mount the tablet, connect wirelessly to the Ditch Assist module, and you’re ready to calibrate. Initial calibration usually involves inputting the antenna height and performing a short self-test where the system cycles the hydraulics to learn the response. In most cases, you can go from unboxing the kit to making your first automated cut in the same day.

Ditch Assist was built to be implement-agnostic and tractor-neutral, meaning you won’t need any special parts from Wolverine’s manufacturer or modifications to your tractor. The standard kit works with closed-center, hydraulic systems, with the option to convert to open-center. All components (valve, control module, cables, and connectors) are designed for the harsh agricultural environment – they’re weatherproof and field-tested in heat, cold, mud, and dust. If you ever want to use Ditch Assist on another implement (say a pull scraper or tile plow), you can do so with minimal extra cost – often it’s just a matter of adding another mounting bracket or power cable, not buying an entirely new system. This reusability and cross-compatibility make Ditch Assist a smarter long-term investment for your farm.

And don’t worry – support is always available if you have questions during setup. Ditch Assist has been field-proven since 2014 and is supported by a network of knowledgeable dealers and the manufacturer’s own team. If you need help with anything from GPS hookup to initial calibration, we’re just a phone call away. Our goal is to ensure you’re comfortable and confident using the system, so you can start seeing the benefits in your field as soon as possible.

Get Your Free No Obligation Consultation Today

Wondering if Ditch Assist is right for yor operation and equipmnent? We only want you to purchase it if it is! Give us a call or fill out our simple request form for honest advice and a tailored solution for your needs

Flexible Hydraulic Control for 3-Point or Trailed Ditchers

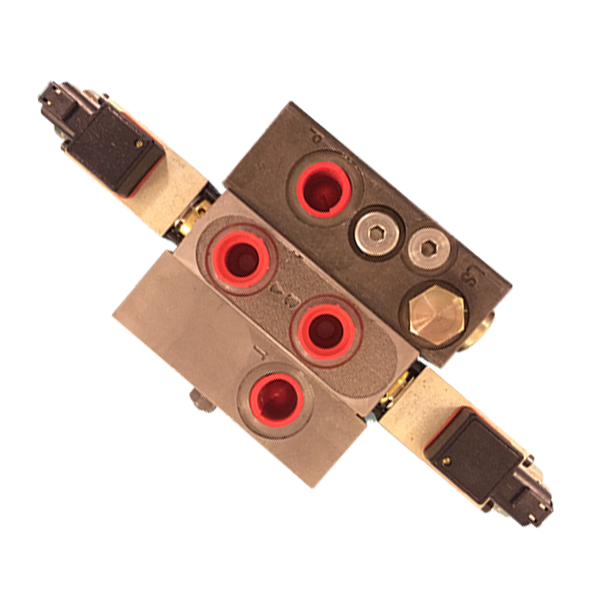

At the heart of Ditch Assist’s automation is its versatile hydraulic valve, which regulates your ditcher’s lift cylinders with precision. This is a rugged proportional PWM valve custom-designed to work with any tractor’s hydraulic system and any implement’s lift mechanism. Whether your Wolverine Ditcher is a newer model or an older unit, mounted on the 3-point hitch or trailed via drawbar, Ditch Assist’s valve can adapt without expensive platform-specific kits. The universality of the hydraulic controller not only saves cost but also simplifies installation across different equipment.

Installation is straightforward and flexible. The valve is typically mounted on the implement itself (often on the Wolverine’s frame or tongue) but can also be mounted on the tractor – whichever best suits your setup. All wiring and components are weather-rated for field use, and the system connects wirelessly to the in-cab tablet, so there are no long cables to route into the cab. In practice, you can install Ditch Assist on a Wolverine Ditcher in an afternoon. Many users weld a small bracket or use an existing mount on each implement they plan to use, making it easy to move the valve module as needed. Because the valve and control module are modular and wireless, switching the entire Ditch Assist system between machines is quick and hassle-free. You could use Ditch Assist on your Wolverine Ditcher this week, then transfer it to a land leveler or scraper next week – the swap can be done in under an hour, getting you back to work quickly. This level of flexibility is a huge plus for operations that utilize multiple tools throughout the year. Ditch Assist essentially provides universal hydraulic grade control that you can take from one implement to another, rather than a fixed one-machine solution.

Get Your Free No Obligation Consultation Today

Wondering if Ditch Assist is right for yor operation and equipmnent? We only want you to purchase it if it is! Give us a call or fill out our simple request form for honest advice and a tailored solution for your needs

Fine-Tuning Performance with Duty Cycle Settings

Every implement’s hydraulic system behaves a little differently – a larger ditcher with a heavy cutting drum and wheel assembly might have slower cylinder response, whereas a smaller ditcher or lighter blade could respond very quickly to inputs. Ditch Assist addresses these differences through adjustable Duty Cycle (DC) tuning in the Ditch Assist app, allowing you to calibrate how aggressively the hydraulic valve corrects the cutting depth. In the app’s settings you can set minimum and maximum duty cycle percentages, effectively controlling the speed and sensitivity of the automatic adjustments. For example, with a very large or heavily loaded implement you might bump up the maximum DC value to get snappier response – the valve will open a bit wider or stay open slightly longer to move that heavy ditcher more quickly. Conversely, for fine grading or a smaller setup, you might dial the settings down so the corrections are more gentle and incremental. These DC adjustments are easy to change on the fly and let you match the system’s behavior to your equipment’s characteristics.

Tuning the responsiveness is key to achieving smooth control: too high a setting on a small implement could cause overshooting of grade; too low on a big ditcher might make corrections sluggish. With Ditch Assist, you simply refine the DC values until the ditcher’s blade reacts promptly but stably to grade commands. The result is a tailored operation – regardless of your ditcher’s size or hydraulic flow rate, you can get the perfect balance of responsiveness and accuracy. This kind of fine-tuning is typically only found in high-end grade control systems, yet Ditch Assist includes it standard via the app. It provides peace of mind that as you change implements or if you feel the movements should be smoother, a few taps in the settings is all it takes to optimize performance. Ditch Assist’s goal is precise control without oscillation, and the DC tuning feature is a big part of delivering that steady, reliable performance for every user.

High-Flow Valve Option for Demanding Hydraulics

Most farm-scale implements – including the Wolverine Ditcher – will work great with the standard Ditch Assist valve. But if you happen to run an exceptionally large ditcher or one with unusually high hydraulic flow requirements, Ditch Assist has a solution for that as well. There is an optional high-flow valve spool available as an upgrade to increase capacity. This high-flow spool is designed to handle greater volumes of hydraulic oil, ensuring that even the biggest equipment can be raised and lowered quickly under automatic control. In practical terms, if your tractor’s hydraulic system or the ditcher’s cylinders demand more flow than the normal valve can comfortably provide, the high-flow upgrade will remove that bottleneck. It’s a simple component swap that can dramatically increase the rate of height adjustment on heavy equipment. By equipping the larger spool, you won’t sacrifice reaction time or accuracy on big jobs – your ditcher will still respond near-instantly to grade changes, even at faster ground speeds or when moving large volumes of soil. No ditching implement is “too large” for Ditch Assist: the system can scale up its hydraulic control capacity to meet the demand. This flexibility means the system is future-proof – if your operation grows into larger, higher-capacity equipment, your Ditch Assist can grow with you.

If you think you might need the high-flow option (this is uncommon unless you know you have a high-GPM tractor or an oversized implement), feel free to discuss it with our team when ordering. We’ll ensure you get the right hardware for your Wolverine Ditcher’s setup so that grade control performance is maximized.

Real-World Applications: Drainage, Water Management & More

One of the best ways to appreciate how Ditch Assist benefits Wolverine Ditcher owners is to look at common use cases. Field drainage is the top application – cutting efficient ditches to remove standing water from low spots or wet areas. With Ditch Assist, you can survey a proposed ditch path and let the system’s Slope-IQ™ feature compute the ideal grade line (or set a target slope manually), then simply drive along as the Wolverine automatically cuts the ditch on grade. The result is a smooth, constant-grade channel that efficiently moves water off your field, with no high spots or reverse grades to cause ponding. Even curved or meandering ditches are possible, following the land’s natural contours while maintaining proper fall. This precision ensures your fields drain properly without guesswork or rework. No more trial-and-error of manually adjusting the ditcher – the system guides the blade to cut exactly to the design grade.

Surface Waterways and Outlets: Many producers use the Wolverine Ditcher to create or maintain shallow grassed waterways and outlet ditches that guide water to the field edge or into drainage canals. Ditch Assist makes this process far more efficient. Instead of eyeballing the grade, you can ensure a consistent slope along the waterway so that water keeps moving steadily. The automation helps prevent “over-cutting” (digging too deep in spots) which can happen with manual control and leads to unnecessary soil disturbance. By maintaining a uniform, gradual slope, you also minimize erosion and make the waterway safer and smoother to cross with equipment after the work is done.

Terrace and Levee Management: In regions where terracing or levees are used for irrigation or erosion control, Ditch Assist can help shape those features with precision. The Wolverine Ditcher is sometimes employed to cut channels or distribute soil when building or repairing terraces and berms. With an RTK-guided grade control, you can ensure each terrace or levee has the correct fall or level grade as per design. For example, users have utilized Ditch Assist to construct large graded terraces for flood irrigation, ensuring each tier is perfectly level or on its intended gradient so water distribution is even. Projects that require very slight grades (a few tenths of a percent or less) are achievable with confidence – simply drive the Wolverine along the terrace line and let Ditch Assist automatically adjust the cut to match the design. This kind of surveyor-grade accuracy was historically very difficult to achieve without expensive equipment, but now your Wolverine Ditcher guided by Ditch Assist can handle it.

Pivot Track Drainage: Center-pivot irrigation systems often leave deep wheel tracks that can collect water and bog down equipment. While dedicated pivot track fillers exist to close those ruts, another approach is to improve drainage around them. Some farmers use their rotary ditchers to cut small drainage furrows leading away from pivot tracks or to re-grade areas around the wheel paths. Ditch Assist can assist in this task by automatically guiding the ditcher to cut a shallow, consistent trench that channels water out of the pivot tracks. By ensuring the trench has the proper slope, water won’t pool in the tracks, helping to prevent pivots from getting stuck in mud. This can be part of an overall field water management strategy in irrigated fields – combining pivot track maintenance with strategic ditching so that excess water is efficiently routed away.

Beyond these examples, Ditch Assist opens up possibilities to use your Wolverine Ditcher in creative ways. Need to smooth out a washed-out gully or re-grade a ditch bank? Set a target slope and let the system do the heavy lifting on getting the correct grade. Because Ditch Assist continuously adjusts on the go, you can tackle projects that involve variable terrain or complex curves with much less effort than manual methods. Producers and land improvement contractors across North America use Ditch Assist on ditchers, scrapers, and blades for a variety of surface drainage and land-shaping projects – often remarking that they wonder how they managed before having automatic grade control.

Learn More about Ditch Assist

Check out the Ditch Assist Product Page for more information and applications

Key Advantages of Ditch Assist for Wolverine Ditcher Owners

Choosing a grade control solution is an important decision. Here are some key advantages Ditch Assist offers for automating your Wolverine Ditcher, especially compared to other options:

-

Broad Compatibility: Unlike some grade-control systems that are tied to a specific machinery brand, Ditch Assist works with any ditcher and any RTK GPS. You can use it with your existing tractor and GPS hardware, saving you from having to invest in brand-specific equipment. It’s a one-stop solution whether you run an Elmer’s Wolverine, a Crary Revolution, an AMCO rotary ditcher, or any other make – and it’s just as at home on a John Deere, Case IH, New Holland, or any tractor with hydraulics. This open compatibility extends to guidance signals as well, so you’re not locked into one ecosystem or forced to buy proprietary GPS subscriptions.

-

Affordability and Value: Ditch Assist is known for being simple and cost-effective without sacrificing capability. It leverages consumer-grade hardware (an Android tablet you may already own or can get for a few hundred dollars) instead of forcing you to buy expensive proprietary monitors. The system itself is typically far less expensive than traditional land leveling or grade control packages, putting high-end capability within reach of the average farmer. Importantly, there are no recurring subscription fees with Ditch Assist and no paid “unlock” codes to get extra features – you receive the full feature set from day one. In short, it delivers advanced grade control functionality at one of the most competitive price points in the industry. This is a big plus for farmers who need professional results but must watch the bottom line.

-

Ease of Installation & Portability: The wireless, modular design makes Ditch Assist extremely easy to install and transfer between equipment. There are no complex harnesses running into the cab – power up the system and it communicates via Wi-Fi, simplifying the install process. Initial setup is quick (often done in an afternoon), and moving the system to another machine later is just as fast. Competing systems might require extensive wiring or dealer calibration each time you switch implements. With Ditch Assist, even a single person can mount the valve, stick on the magnetic control module, and be operational with minimal help. This plug-and-play simplicity reduces downtime and frustration. If you have multiple implements (for example, you might use the Wolverine Ditcher in spring and a scraper or blade in fall), you can share one Ditch Assist system among them – maximizing your investment.

-

Powerful Features = Better Results: Ditch Assist’s software is packed with advanced features typically found only in much pricier systems. The Slope-IQ™ technology, for example, automatically calculates best-fit grades from your survey data, so you don’t have to do manual grade calculations or guess the ideal slope. You can also design curved or variable-grade ditches easily, which is nearly impossible with basic laser setups. The Auto Nudge feature (optional to enable) can intelligently limit your cut depth per pass, preventing the ditcher from biting off more than it should at once – this avoids stalling the tractor or creating big soil berms, and makes multi-pass digging more efficient. Ditch Assist also allows you to import external design files for complex land shaping projects, use the system in a survey-only mode to map elevations, and more. All these capabilities come in a user-friendly app that receives free updates over time. Competing solutions – whether laser-based or older GPS systems – often lack such flexibility or charge extra for each of these capabilities. With Ditch Assist you get everything in one package, which means greater versatility on the job and superior ditching outcomes (uniform slopes, no over-cutting, and no missed low spots).

-

Reliable Performance & Support: Since its introduction in 2014, Ditch Assist has been field-proven across countless jobs – from prairie farm ditches to large-scale land leveling in South America. It’s engineered and built by drainage experts who understand the challenges of real-world farming and earthmoving. Users run it season after season on their equipment, attesting to its durability and consistent performance. Should you ever have questions or need assistance, you have access to a support network of knowledgeable dealers as well as the manufacturer’s own team. We take pride in providing prompt, helpful support and continuously improving the system via software updates (often driven by user feedback). When you choose Ditch Assist, you’re not just buying a gadget – you’re investing in a complete solution with ongoing development and support. This gives peace of mind that your grade control system will remain up-to-date and reliable for years to come.

In summary, Ditch Assist offers a combination of flexibility, functionality, and cost-effectiveness that is hard to beat in the realm of GPS grade control. It adapts to your unique scenario – whether you’re a farmer draining a few low spots with your Wolverine Ditcher, or a contractor building miles of drainage ditches – and it does so with a level of precision and simplicity that makes the job easier. By integrating Ditch Assist, your Wolverine Ditcher becomes a smart, automated earthmoving tool that saves you time, labor, and guesswork while delivering better results in the field.

Ready to take your Wolverine Ditcher to the next level? Contact us today to learn more about how Ditch Assist can fit into your operation, or to schedule a free consultation. With Ditch Assist guiding your Wolverine, you’ll ditch smarter, not harder, and see the difference in your fields after the next rain. Let’s get your water management on grade!

Learn More about Ditch Assist

Check out the Ditch Assist Product Page for more information and applications