Pull-Type Scraper Grade Control with Ditch Assist

Ditch Assist™ is the simplest and most affordable RTK GPS grade control system for pull-type scrapers. Advanced features. No unlocks or subscriptions.

Pull-Type Scraper Grade Control with Ditch Assist

Ditch Assist™ is the simplest and most affordable RTK GPS grade control system for pull-type scrapers. It delivers advanced grade automation features in a plug-and-play package – with no costly unlocks or subscriptions needed. Whether you’re a farmer, contractor, or landowner looking to automate a scraper for land leveling or ditching, Ditch Assist provides precision scraper control without the complexity or high price tag. (Many users switch to Ditch Assist after struggling with more expensive, complex systems, finding our solution gives them all the functionality they need — minus the headaches.)

👉 Interested in upgrading your scraper? Get a Quote or Free Consultation and discover how easily Ditch Assist can fit your operation.

How Ditch Assist Simplifies Scraper Grade Control

Ditch Assist is an RTK GPS machine control system that automates the raise/lower function of your pull scraper’s blade to maintain your target grade. In practice, it works just like the big expensive construction systems, but in a simpler, farmer-friendly form. Set your desired slope or grade, and as you drive, Ditch Assist automatically adjusts the scraper hydraulics to stay on grade – whether you’re cutting drainage ditches or leveling a field or building pad. The system works with any hydraulically operated pull-type scraper, regardless of brand or age, essentially turning any scraper into a precision land leveling tool. (It’s also a universal solution for land levelers, ditchers, and similar implements, making it versatile for various earthmoving projects.)

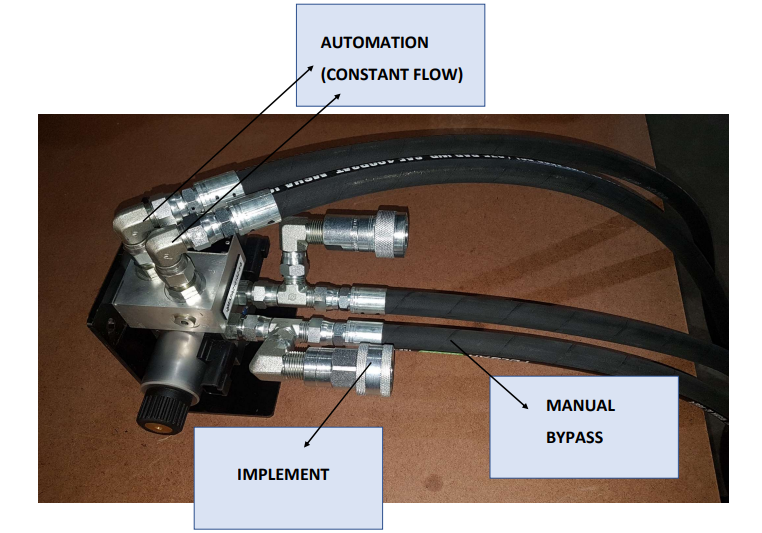

One of the key hardware components is the Ditch Assist Full Automation Kit, which includes everything you need to equip your scraper for automatic grade control. This kit provides a rugged proportional hydraulic valve plus all necessary hoses and fittings to tie into your scraper’s existing hydraulics. Importantly, the valve is designed with a built-in hydraulic bypass circuit, which means you retain full manual control of your scraper at all times. Simply use your tractor’s hydraulic lever and you can override the system instantly whenever needed. Ditch Assist adds GPS automation without taking away your ability to make manual adjustments – a reassuring feature for operators who want that flexibility and safety net.

(Wondering if Ditch Assist will work for your specific scraper or project? We only want you to purchase if it’s truly right for you. Feel free to contact us for a no-obligation consultation – we’ll give honest advice and help tailor a solution to your needs.)

Universal RTK GPS Compatibility – Use Any Receiver You Have

Accuracy in grade control is only as good as the positioning data you feed it. Ditch Assist is built to leverage high-precision RTK GPS for sub-inch accuracy, and it works with virtually any RTK-capable GPS receiver you might use. The system is completely GPS brand-agnostic – as long as your receiver outputs standard NMEA messages (nearly all do), you can plug it into Ditch Assist and get straight to work. This means you can likely use the GPS equipment you already own. For example, many Ditch Assist users connect it to their John Deere, Trimble, Outback, or Ag Leader receivers on their tractors, provided those receivers are unlocked for RTK or a similar high-accuracy signal. If your current GPS isn’t RTK-ready, you have a couple of cost-effective options: you can unlock/upgrade your existing receiver to RTK through your GPS dealer, or opt for an affordable RTK unit.

One popular low-cost RTK option is the Emlid Reach series of GPS receivers – for instance, the Reach RS2/RS3 units offer full RTK capability at a fraction of the cost of traditional ag GPS systems. Ditch Assist interfaces with these receivers seamlessly, giving you an economical path to top-grade accuracy. In short, “any GPS” will work – you can use your existing RTK setup, upgrade a capable receiver, or purchase a new budget-friendly RTK receiver to pair with Ditch Assist. This freedom to mix and match means Ditch Assist fits into your precision ag ecosystem without forcing you to buy proprietary hardware or subscriptions. (You won’t be locked into one brand’s GPS or required to invest in a specific monitor just to run grade control.)

If you’re unsure about compatibility or need guidance on GPS choices, our team is happy to help – give us a call at 1-877-354-2899 or reach out via our contact form.

Bottom line: Ditch Assist works with any RTK GPS source you choose, so you’re not left needing expensive brand-specific GPS hardware to get started.

Plug-and-Play Installation on Any Tractor

You don’t need to be highly technical or modify your tractor to install Ditch Assist – it’s designed for quick, plug-and-play setup. Mount the Ditch Assist valve and control module on your scraper (usually on the hitch tongue or frame) and tee the provided hoses into the scraper’s lift hydraulic lines. Then connect the power cable to your tractor’s battery and plug the GPS cable into your receiver. That’s it for wiring – there’s no complex harness into the cab required. The Ditch Assist control module creates its own secure Wi-Fi network to communicate with the in-cab display, so the system is wireless between the scraper and the cab. Fewer cables mean faster installation and less hassle (no long wires to snake through joints or worry about snagging).

Once the hardware is mounted and connected, simply fire up the Ditch Assist app on a standard Android tablet in your cab. (Any off-the-shelf Android tablet 8-10 inches or larger will work – there’s no proprietary screen needed.) Connect the tablet to the Ditch Assist module’s Wi-Fi and you’re ready to calibrate and start moving dirt. The app’s interface is intuitive and user-friendly, with on-screen prompts to set your target grade, view real-time cut/fill depths, and adjust settings. Even first-time users quickly get the hang of it – if you can use a smartphone or basic GPS, you can operate Ditch Assist. The familiar touchscreen experience and simple controls take the stress out of maintaining grade, letting you focus on driving safely while the system handles the blade.

Importantly, Ditch Assist doesn’t depend on any particular tractor make or model. It works on all brands of tractors, old or new, because it operates independently of the tractor’s internal guidance or hydraulic systems. You can install it on your older 2WD John Deere or on a brand-new 4WD Case IH – as long as the tractor has standard hydraulic remotes for the scraper, Ditch Assist can be hooked up. If your tractor does have an auto-steer guidance system (e.g. John Deere AutoTrac, Trimble Autopilot, etc.), you can absolutely use that in tandem with Ditch Assist. In fact, many customers do: they let the tractor drive the guidance line via auto-steer while Ditch Assist controls the blade height, creating a highly automated earthmoving setup that rivals far more expensive machines. On the other hand, if your tractor doesn’t have GPS steering, no problem – you can drive manually using the guidance bar on the Ditch Assist app (it shows you whether you’re on the designed path and indicates if the blade is on grade or needs adjustment). Either way, Ditch Assist is compatible with any tractor and any guidance approach you prefer. There’s also no concern about different hydraulic types: the included valve works with both open-center and closed-center hydraulic systems, so you don’t need any special tractor modifications or dealer programming. It’s truly a universal add-on that you can easily move from one tractor to another as needed.

Lastly, because Ditch Assist is completely portable, you aren’t forced to dedicate one machine to it. You can use it on a scraper in the fall for field drainage, then swap it over to a land leveler in the spring for seedbed prep, or even lend it to a neighbor. If you trade tractors, you can take Ditch Assist along to the new machine without compatibility worries. This flexibility means one system can service multiple implements or tractors, maximizing your investment and adapting as your equipment or projects change.

Get Your Free No Obligation Consultation Today

Wondering if Ditch Assist is right for yor operation and equipmnent? We only want you to purchase it if it is! Give us a call or fill out our simple request form for honest advice and a tailored solution for your needs

Universal Hydraulic Valve – One Kit Fits All Scrapers

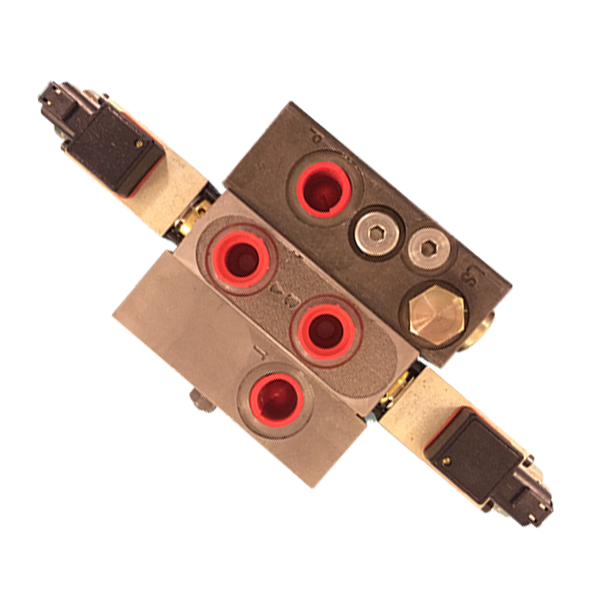

At the heart of Ditch Assist’s system is a versatile proportional hydraulic valve that makes the magic happen. Unlike some brand-specific valves or add-ons, the Ditch Assist valve is truly universal – it’s custom-designed to work with virtually any tractor’s hydraulics and any pull-type scraper’s cylinders. Whether your scraper is an Ashland, Degelman, K-Tec, Leon, Grouser (or any other make) and whether your tractor’s hydraulic system is open-center or closed-center, the Ditch Assist valve can handle it. There’s no need to buy expensive model-specific hydraulic kits for different tractors or scrapers; the same Ditch Assist valve module adapts to all, saving you money and simplifying setup across your equipment fleet.

This valve is a heavy-duty PWM (pulse-width modulated) valve that precisely controls the flow of hydraulic oil to raise or lower the scraper blade smoothly. You typically mount the valve block right on the scraper (often on the tongue or frame) for the cleanest installation. Optionally, it could be mounted on the tractor if that suits your setup better – whatever keeps the hoses tidy. Because the Ditch Assist valve and control module are self-contained and easily detachable, you can swap the whole system between machines with minimal hassle. In fact, many users weld a small bracket or plate on each implement they plan to use (like each scraper or ditcher), so they can quickly move the valve and control module from one to another. Wireless control means you don’t have to reroute long cables when switching – just relocate the module, hook up a couple of hoses, and you’re good to go. In practice, you can transition Ditch Assist from one scraper to another (or one tractor to another) in well under an hour. This level of portability is a huge advantage for operations that use multiple implements: one Ditch Assist system can automate all of them, one at a time, instead of needing separate expensive kits for each machine.

While Ditch Assist automates blade control, it never “locks you out” from controlling your equipment. Thanks to the built-in bypass circuit mentioned earlier, you can grab the tractor’s hydraulic lever at any time to manually raise or lower the scraper. The Ditch Assist valve will gracefully yield to your command (so you’re not fighting the system), and as soon as you’re done and let go, the automatic control resumes keeping grade. This manual override capability gives operators confidence to trust the system – you remain in ultimate control, and you can instantly correct or adjust anything on the fly. Many users find this feature invaluable, for example when encountering an unexpected obstruction or when needing to pull out of a cut quickly; you don’t have to pause or disable anything, just use your hydraulics as normal. The system design adds automation without ever taking control away from you.

In summary, the Ditch Assist hydraulic valve and control module are built for maximum compatibility and ease of use: any make of scraper, any model of tractor, and any hydraulic configuration can be accommodated. You get robust automatic grade control on virtually any scraper setup, all through one standardized kit. It’s a truly plug-and-play grade control solution for pull scrapers, rather than a complicated OEM-specific installation.

Get Your Free No Obligation Consultation Today

Wondering if Ditch Assist is right for yor operation and equipmnent? We only want you to purchase it if it is! Give us a call or fill out our simple request form for honest advice and a tailored solution for your needs

Fine-Tuning Performance with Adjustable “Duty Cycle” Settings

Every scraper’s hydraulic system behaves a little differently – a large pull-pan with a 12-foot blade might respond slower or weigh more than a smaller box scraper, for instance. Ditch Assist accounts for these differences by allowing you to fine-tune the hydraulic response via Duty Cycle (DC) settings in the app. This feature lets you adjust how aggressively the valve corrects the blade height, by setting minimum and maximum duty cycle percentages (which essentially control the speed and frequency of blade adjustments). It sounds technical, but it’s presented in a simple way in the app’s settings.

For example, if you’re using a big scraper with a heavy blade, you might increase the minimum and maximum duty cycle values so that the valve opens a bit wider or stays open slightly longer when making a cut. This yields a snappier response, helping the system move that heavy blade quickly to the target grade. Conversely, for a small scraper or for very fine grading, you might dial the settings down so the blade adjusts more gently and incrementally. That prevents overshooting the grade on a lightweight implement. These DC settings are easy to tweak on the fly, and they let you match the system’s behavior to your specific equipment and preferences. Users report that this tuning capability is key to achieving butter-smooth control – too high a correction speed on a small scraper could cause oscillation or overshooting, while too low on a large scraper might make grade corrections lag. With Ditch Assist, you simply refine the DC values until the scraper’s reactions are just right for your scenario.

The result is a tailored, optimized performance: regardless of scraper size or hydraulic flow rate, you can get the perfect balance of responsiveness and accuracy. Notably, this kind of fine-tuning is typically found only in high-end grade control systems (often behind expensive “pro” settings unlocks), yet Ditch Assist includes it standard, at no extra cost. It gives you peace of mind that as you change implements, or if you feel the blade movements need to be smoother, a few taps in the app is all it takes to dial it in. Our goal is to provide precise control without unnecessary blade oscillation, and the duty cycle tuning feature helps deliver that stability for every user.

High-Flow Valve Option for Larger Scrapers

Most pull-type scrapers on farms will work great with the standard Ditch Assist valve, but if you happen to run an extra-large scraper or one with exceptionally high hydraulic flow requirements, Ditch Assist has a solution for that as well. There is an optional high-flow valve spool available as an upgrade for the Ditch Assist hydraulic valve. This high-flow spool is designed to handle greater volumes of hydraulic oil, ensuring that even the biggest construction-grade or high-capacity land leveling scrapers can be raised and lowered quickly under automatic control. In practical terms, if your scraper’s hydraulics are so robust that the normal valve struggles to keep up with the flow or speed, the high-flow spool will alleviate that bottleneck.

For customers with very large scrapers, it’s recommended to discuss this option with the Ditch Assist team prior to purchasing to make sure we set you up with the right hardware. The high-flow valve is a simple component swap that can dramatically increase the rate of blade response on heavy equipment. By equipping the larger spool, you won’t sacrifice reaction time or accuracy on big jobs – your blade will still respond instantaneously to grade commands, even at faster ground speeds or with heavy loads. Rest assured, no scraper is “too large” – Ditch Assist can scale up its hydraulic control to meet the demand. This flexibility means the system is future-proof; if your operation grows into larger scrapers, your Ditch Assist can grow with you by utilizing the high-flow valve option.

Real-World Applications: Ditching, Land Leveling, and More

One of the best ways to understand Ditch Assist is to see what it can do in real-world projects. Pull-type scrapers are incredibly useful in both agriculture and earthmoving, and Ditch Assist unlocks their full potential for precision work. Here are a few common applications and how the system shines in each:

-

Surface Drainage Ditching: Creating or maintaining field ditches for drainage becomes far easier with Ditch Assist automation. Traditionally, operators often relied on guesswork or manual laser systems to cut a ditch with the right grade; now you can survey a proposed ditch path and let Ditch Assist’s built-in design tool (Slope-IQ™) compute the ideal grade line automatically. Alternatively, you can set a target slope or grade manually. Then, simply drive along the flagged path as the scraper cuts the ditch automatically on grade. The result is a smooth, constant-grade ditch that efficiently moves water off your fields. Even curved or variable-slope ditches are possible – Ditch Assist will follow the land’s natural contours while maintaining the proper fall. This level of precision ensures your fields drain properly without the need for guesswork or repeated passes to get the slope right.

-

Land Leveling & Field Smoothing: Whether you’re preparing land for flood irrigation, leveling a rough field for planting, or repairing erosion washouts, Ditch Assist is a game-changer for land leveling tasks. You can use the system to achieve a completely flat plane or a uniform gentle slope across an area. By setting a target grade of zero (level) or a specific slope, the scraper will automatically cut high spots and fill low spots as you drive, resulting in a perfectly graded field or pad. Farmers and contractors use Ditch Assist for field leveling because it consistently delivers the uniform results needed for even crop growth and efficient irrigation. It essentially turns a standard pull scraper into a precision land-leveling machine. You can even take it a step further and import a complex 3D land design (for example, a design created in software like OptiSurface™, AgForm3D™, or TerraCutta) into the Ditch Assist app – the system will then guide the scraper to implement that design exactly on the ground. This capability allows advanced land-forming projects to be carried out with an ordinary pull scraper and tractor, something historically only possible with specialized (and very expensive) equipment.

-

Precision Land Forming for Irrigation: In water-intensive farming (like rice fields or leveled irrigation basins), maintaining extremely precise grades is critical – often targeting slopes of only 0.1% or even dead-level terraces. Ditch Assist provides the control needed to achieve these exacting standards. The system can hold a consistent grade or elevation to within a few tenths of an inch, ensuring water flows evenly or sits level where intended. For example, users have utilized Ditch Assist to construct large tiered irrigation paddies, ensuring each terrace is perfectly level or on the exact designed gradient so that water distribution is uniform. With RTK GPS accuracy and automatic blade control, you can attain surveyor-grade precision in your earthmoving. Projects that involve multi-slope designs, contour levees, or broad-acre leveling are all within reach – you simply drive the tractor and let Ditch Assist continuously adjust the blade to keep you on spec.

-

Building Pads and Construction Site Prep: Beyond agriculture, many folks have found Ditch Assist invaluable for creating flat building pads (for grain bins, barns, driveways, even house foundations) and grading rural construction sites. The principle is the same as field leveling – input the desired elevation or grade, and let the system guide the scraper to cut and fill accordingly. The advantage over eyeballing with a skid steer or tractor blade is the uniformity and accuracy you get: for instance, if you need a pad at exactly 1400.00 feet elevation, Ditch Assist will hold that elevation across the entire site, something nearly impossible to do by eye. In effect, you’re using your farm scraper like a precision bulldozer controlled by GPS. Because Ditch Assist maintains grade automatically, you also avoid moving more dirt than necessary – it only cuts where there’s excess high ground and drops that material into low spots, optimizing each pass. Customers report significant time and material savings on projects like leveling building sites or constructing drainage terraces, because the system guides them to exactly where dirt needs to be removed or added, eliminating a lot of trial and error.

In all of these scenarios, Ditch Assist delivers the accuracy and consistency that boost productivity and quality of work. Farmers and contractors who adopt the system on their pull-type scrapers often wonder how they managed before. The combination of easy surveying/design (with tools like Slope-IQ for best-fit grades) and hands-free control means you can take on complex grading jobs with confidence. It’s no surprise that Ditch Assist is now widely used by producers and land improvement contractors across North America and beyond for projects requiring precise surface drainage and land forming. Whether you’re installing subsurface tile and need matching surface ditches, or tackling full-field leveling, a pull scraper guided by Ditch Assist becomes a powerful precision tool in your arsenal.

Learn More about Ditch Assist

Check out the Ditch Assist Product Page for more information and applications

Key Advantages – Why Choose Ditch Assist for Scraper Automation?

Choosing a grade control solution for your scraper is an important decision. Here’s how Ditch Assist stands apart from other options:

-

Broad Compatibility (Any Brand, Any Setup): Ditch Assist isn’t tied to a single brand or ecosystem. It works with any pull-type scraper – whether you run Ashland, Degelman, K-Tec, Leon, or any other make – and it’s equally at home on any tractor (John Deere, Case IH, New Holland, Cat Challenger, older tractors or new). It also works with any RTK GPS receiver you prefer. This open compatibility means you can likely integrate Ditch Assist with the equipment you already own, instead of investing in brand-specific monitors or receivers. You’re not locked into a proprietary system or forced to buy additional components from a single manufacturer. Ditch Assist is a one-stop solution that can adapt to your existing fleet and precision ag platforms, which protects your investment long-term.

-

Affordability with No Hidden Fees: Ditch Assist is known for being affordable without sacrificing capability. In many cases it costs significantly less than traditional laser leveling or OEM GPS grade control packages. One reason is that it leverages hardware you might already have (like an Android tablet or your current GPS) instead of making you purchase costly proprietary displays or new GPS units. More importantly, there are no recurring subscription fees charged by Ditch Assist, and no feature “unlock” activation charges – you get the full feature set from day one. Advanced capabilities like multi-slope design, data recording, or importing designs are included (whereas some competitor systems make you pay extra for each module). In contrast, some popular grade control solutions require buying brand-specific control boxes and multiple software unlocks that can add thousands of dollars in extra costfarmprogress.com. With Ditch Assist, what you see is what you get: a complete, fully functional system for one honest price. This value proposition is a big plus for farmers and small contractors who need professional results on a budget. (In fact, many Ditch Assist customers have replaced more expensive brand-name systems after realizing they were paying a premium for features or subscriptions they didn’t truly need.)

-

Easy Installation & Portability: Unlike some systems that involve complex installation or dealer-only setup, Ditch Assist is designed for easy DIY installation. The wireless, modular design means there are no bulky harnesses to run into the cab or intricate calibration procedures on each use. Most users can mount and configure Ditch Assist in an afternoon with basic tools. Once installed, the system is just as easy to remove and transfer to another machine. Competing systems often require extensive rewiring or recalibration if you move them, but Ditch Assist’s quick-connect hoses and wireless module make transfers straightforward. Even a single operator can mount the valve, stick the magnetic control module on, and be up and running with minimal assistance. This plug-and-play simplicity reduces downtime and lets you get more use out of the system (one unit can service multiple pieces of equipment through the year). If you’re a do-it-yourselfer or operating in a remote area, you’ll appreciate not having to rely on a technician every time you want to set up or move your grade control system.

-

Advanced Features Included: Ditch Assist’s software is packed with powerful features typically found only in high-end systems – except we include them at no extra charge. For example, our Slope-IQ™ technology automatically calculates best-fit slopes/grades between surveyed points, saving you time on design work and ensuring optimal drainage paths. The Auto–Nudge feature (optional to use) can limit your cut depth per pass, preventing the scraper from biting off more than it should and stalling your tractor – this effectively adds intelligence for multi-pass earthmoving, so you can take deep cuts in layers rather than all at once. You can also import external design files for complex landforming projects, use Ditch Assist in a survey-only mode to map field elevations, and more. All these capabilities come in a user-friendly app that we continually improve. (Software updates are provided free via download – no subscription or update fees.) Competing solutions – whether old-school laser systems or other GPS packages – often lack some of these flexible features, or they charge hefty fees to unlock themditchassist.comditchassist.com. With Ditch Assist you get everything in one package, which means greater versatility on the job without the nickel-and-diming.

-

Proven Performance & Support: Since its introduction in 2014, Ditch Assist has been field-proven across countless jobs and environmentsditchassist.com. From prairie farm ditches in Canada to large-scale land leveling in South America, the system has demonstrated reliable performance season after season. The hardware is built tough for outdoor use, and the control algorithms are the result of years of refinement by experts who understand real-world grading challenges. When you choose Ditch Assist, you’re not only getting a product, but also the backing of a dedicated support network. We have knowledgeable dealers in many regions and a responsive manufacturer support team ready to help with any questions. Our customer service is often cited as a reason people love the product – we’ll work with you to ensure you’re successful. Additionally, the software is continuously evolving with new features and improvements driven by user feedback. In short, you’re investing in a solution that keeps getting better. If you ever need assistance, we’re just a phone call away, and we stand behind the system 100%.

In summary, Ditch Assist offers a combination of simplicity, flexibility, and cost-effectiveness that is hard to beat in the world of pull-scraper grade control. It adapts to your unique scenario – whether you’re a farmer leveling 40 acres for irrigation, or a contractor digging miles of drainage ditches – and gives you confidence that the job will be done right. By automating the tedious task of holding grade, it frees you up to focus on operating safely and efficiently. The end result is higher productivity, more precise outcomes, and a fast return on investment through time and material savings.

If you’re considering upgrading your pull-type scraper with GPS automation, Ditch Assist is a proven choice that checks all the boxes. Why put up with over-complicated or overpriced systems when a simpler, more affordable solution is available? Get in touch with us today to learn more or to discuss your specific needs. We’ll make sure you get a configuration that works perfectly for your equipment and terrain. With Ditch Assist on your scraper, you can tackle drainage, land leveling, and earthmoving projects with greater accuracy, confidence, and ease – and start reaping the benefits of modern grade control right away.

Learn More about Ditch Assist

Check out the Ditch Assist Product Page for more information and applications