Excavator Grade Control Powered by Ditch Assist™

Expand your Ditch Assist™ system to excavators and backhoes for accurate RTK grade guidance without lasers, guesswork, or hassle.

Dig On Grade™ with Ditch Assist X™

Ditch Assist X™ expands your original Ditch Assist system, bringing precise RTK GPS grade guidance directly to your excavator or backhoe. Engineered by Northern Plains Drainage Systems, Ditch Assist X delivers real-time bucket elevation guidance, enabling accurate grading without relying on lasers or guesswork. Designed to integrate into your existing workflow, it’s easy to install, intuitive to use, and perfect for achieving professional-grade excavation results every time.

Ditch Assist X Features

✅ Expands Ditch Assist Functionality to Excavators

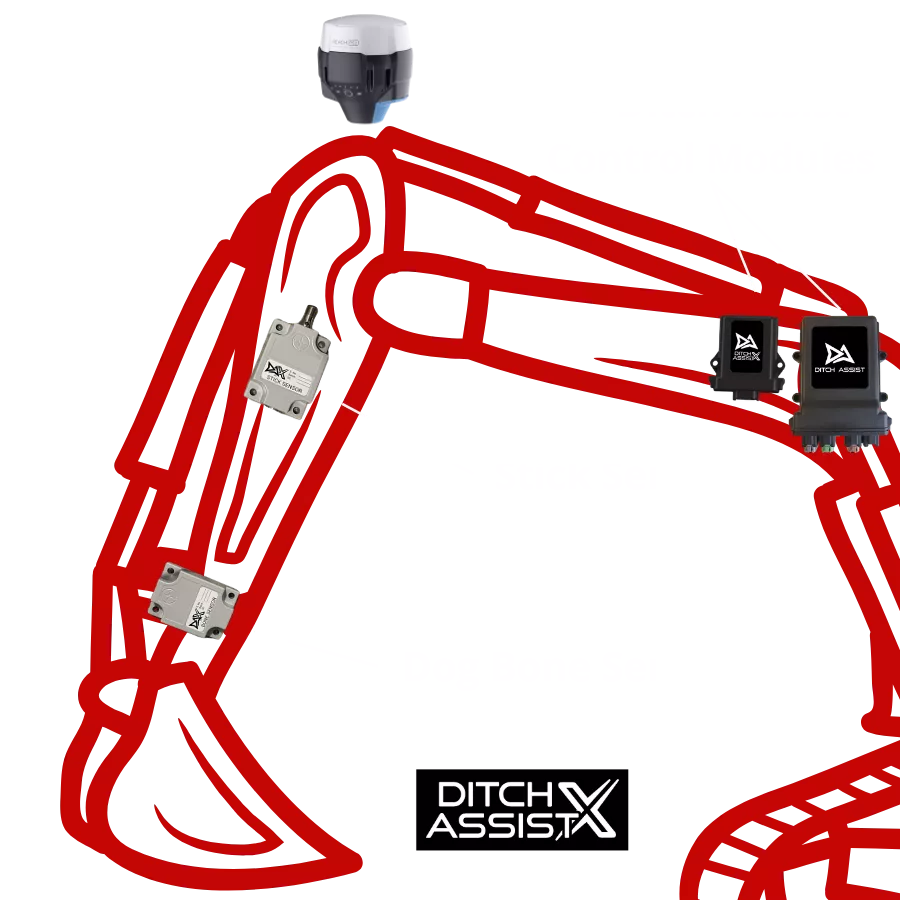

By adding the Ditch Assist X Kit to your existing system, you unlock even more value. X includes two rugged inclination sensors, a compact control module, and our proprietary GPS pendulum mount system—enhancing your current Ditch Assist Control Module and harness. The result? Real-time, accurate bucket elevation guidance for excavators and backhoes at any digging position.

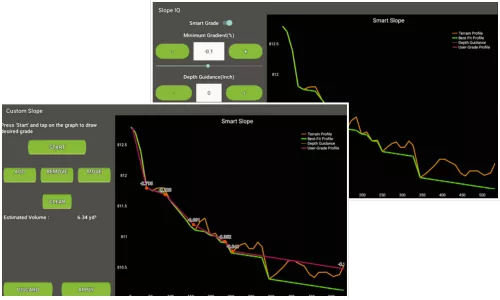

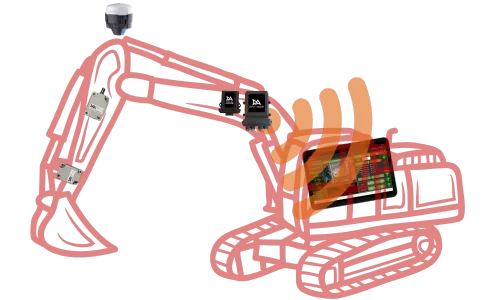

✅ Same Familiar Android-Based User Interface

Ditch Assist X uses the familiar Ditch Assist Android app to deliver advanced excavation capabilities. Running on affordable, widely available Android tablets (like Samsung Galaxy devices), the app eliminates the need for costly proprietary displays or Windows-based solutions—bringing real-time bucket elevation guidance right to your fingertips. With Ditch Assist X, you can take advantage of the same surveying and design tools used by Ditch Assist users, allowing for best-fit or custom designs, curved routes, and the ability to import surveys and designs. Download the latest version directly from our App Downloads page or ask us about preconfigured tablets.

✅ Same Industry-Leading Wireless Connectivity

✅ Advanced Functionality and Customization

✅ Ultra Rugged High Accuracy Inclination Sensors

✅ Universal GPS Compatibility

Ditch Assist X, or DAX as we call it, includes everything needed to add excavator guidance to an existing Ditch Assist system. To integrate DAX, you'll need the Control Module, main harness, power harness, and GPS cable from your standard Ditch Assist Kit. DAX then adds a pair of ultra-rugged, high-precision inclination sensors, a dedicated DAX Control Module, and our proprietary GPS pendulum mounting system—ensuring unmatched bucket elevation accuracy for your excavator or backhoe.

Ditch Assist X Components

Have Questions about Ditch Assist X?

We'd love to chat! Talk to one of our product specialists today

Typical Ditch Assist X Setup

GPS Pendulum Mount

The mount mast is typically permanently installed (welded) on the machine, positioned at the top of the stick so that the pendulum pivot point is above the boom-stick pivot.

Control Modules

Both the Ditch Assist™ and Ditch Assist X™ Control Modules can be conveniently mounted outside near the cab using the provided magnet mounts. A single power cable connects to the machine's battery, one cable interfaces with the GPS receiver, and a dedicated cable connects to the two sensors.

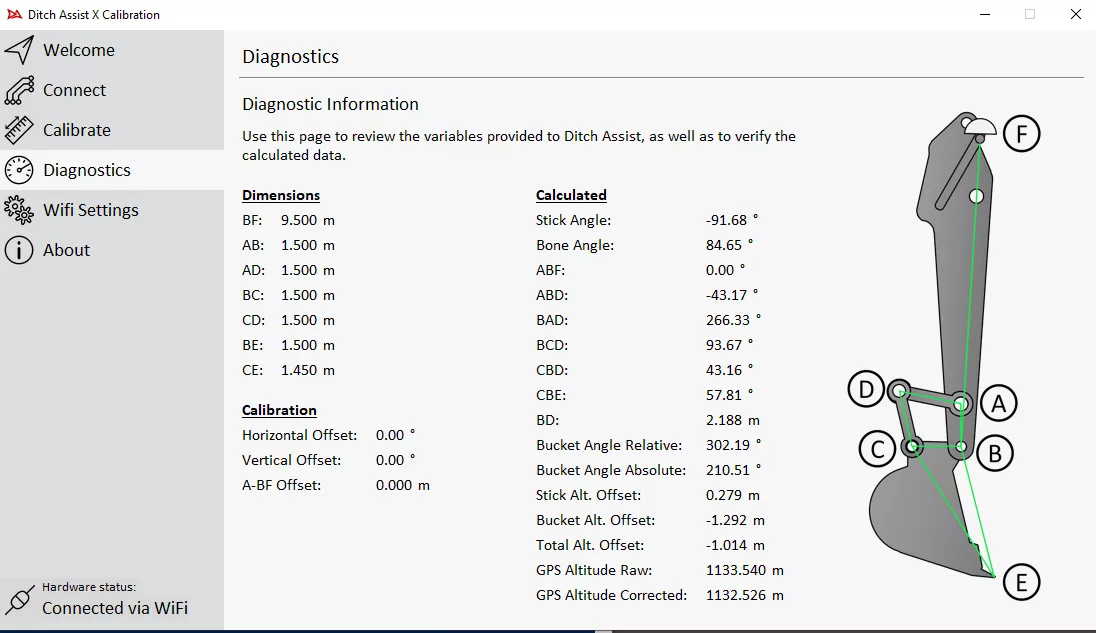

Calibration Steps

Calibrating Ditch Assist X is essential yet straightforward when you follow the detailed instructions in our calibration app. First, install the small Windows calibration program on your PC and connect to the Ditch Assist X module via Wi-Fi. The app will guide you through several steps where you position the machine in various states and take measurements between key components. You'll set both vertical and horizontal levels—ensuring the bucket, stick, boom linkages, and attachment points are aligned. For this process, you'll need a step ladder to access the GPS mounted at the top of the stick when vertical, a metric tape measure, an accurate level, and a plumb bob. Calibration typically takes less than 30 minutes, and all values are saved in the Control Module, so you only need to recalibrate if you relocate the sensors or move the system to another machine. We recommend recording the measurements for easy re-entry when switching machines regularly.

Which Excavator Guidance System is Right for You?

We offer two excavator guidance options because operators have different needs—not because one is “better” than the other. The right choice depends on how you work.

Ditch Assist DIG™ — Fast, Simple, Standalone Grade Guidance

DIG is for operators who want the simplest, most cost-effective way to dig to grade with RTK accuracy. It’s a dedicated excavator solution—no extra hardware, no DA system required, and no design prep or mapping knowledge needed.

Best for:

✔ Digging to a set grade (municipal drainage, contractors, trenching, tile mains, water/sewer runs, culvert work, slope maintenance)

✔ Operators who value speed, simplicity, and low cost of ownership

✔ Crews that don’t need mapping, designs, or CAD-style workflows

Why choose DIG:

-

Purpose-built for excavators

-

Set grade → dig → done

-

Fastest to learn and use daily

-

No Ditch Assist system required

-

Typically 1/2 the cost of X (complete system)

DIG is the 80% solution for 80% of excavator jobs — and the one operators actually use every day.

Ditch Assist X — Advanced Surveying & Design for Power Users

Ditch Assist X is for operators who want survey, mapping, and design tools on top of grade guidance. It’s an expansion of the full Ditch Assist system, so it’s ideal for users who already own DA or who want the flexibility to use both excavators and surface equipment with one platform.

Best for:

✔ Users who want to survey, design, and plan jobs in the field

✔ Creating best-fit or multi-segment designs (e.g., curved ditches, grade optimization)

✔ Users already running Ditch Assist on scrapers, ditchers, or blades

Why choose X:

-

Survey and map your route before digging

-

Design slopes, breaks, and variable grades

-

Import simple design files with target elevations

-

Works with the full Ditch Assist app ecosystem

-

Ideal if using DA on multiple machines

If you need to design jobs before digging, X gives you those tools. If you’re mostly digging to a known grade, DIG is the smarter fit.

✅ What Both Systems Do

Both DIG and X will let you:

✔ Dig to a fixed elevation or set grade

✔ Maintain correct slope between two points

✔ Use grade breaks for multi-segment runs

✔ Install quickly, run wirelessly, and use RTK for high accuracy

Both are 2D guidance tools — focused on keeping the bottom of your trench/ditch on grade.